Feedstock of the future

Algae, with their many potential uses in medicine and as a superfood or biofuel, could help feed the world and benefit the climate. We reveal what makes them the natural resource of the 21st century – and how Phyox is taking its algae cultivation to the next level.

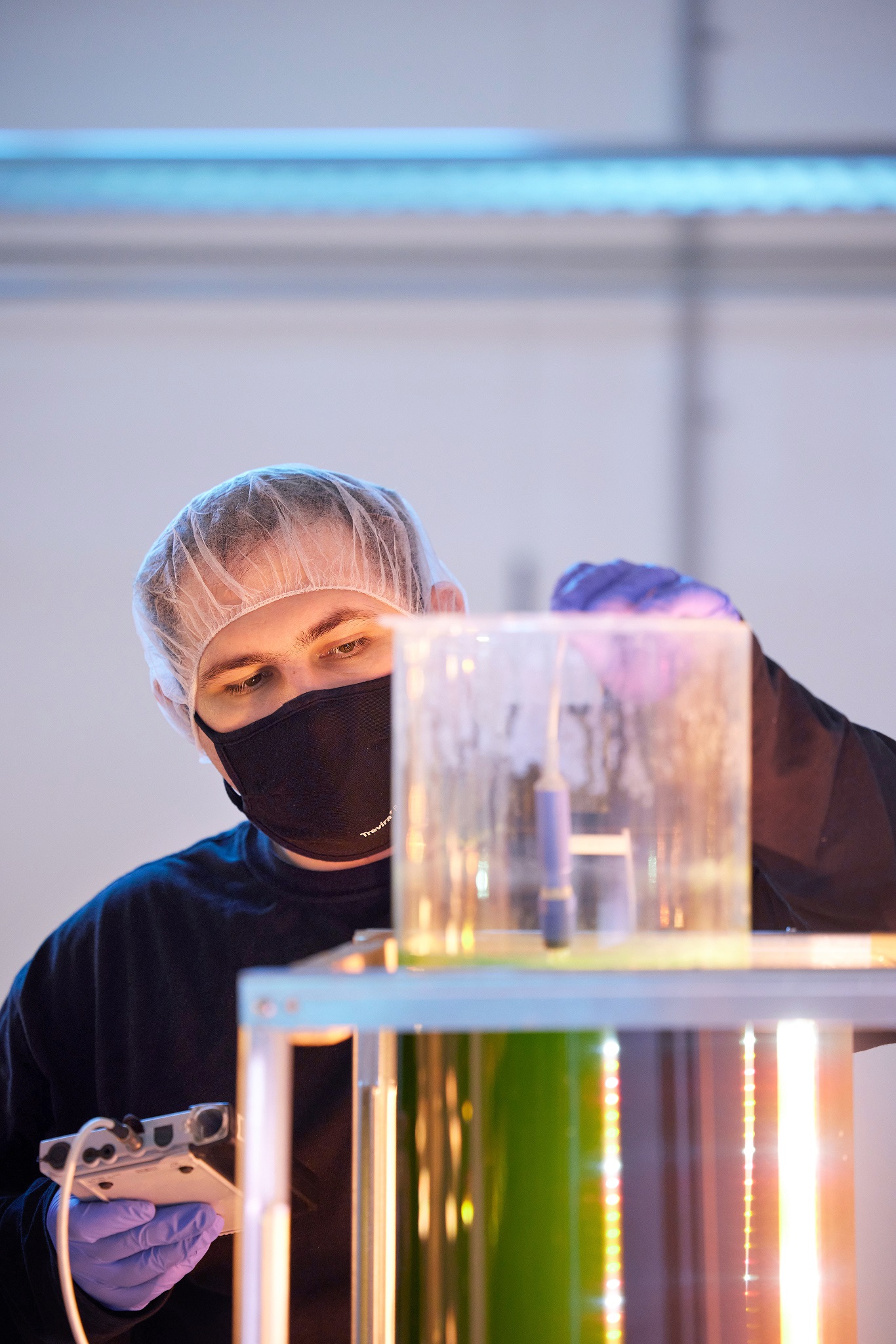

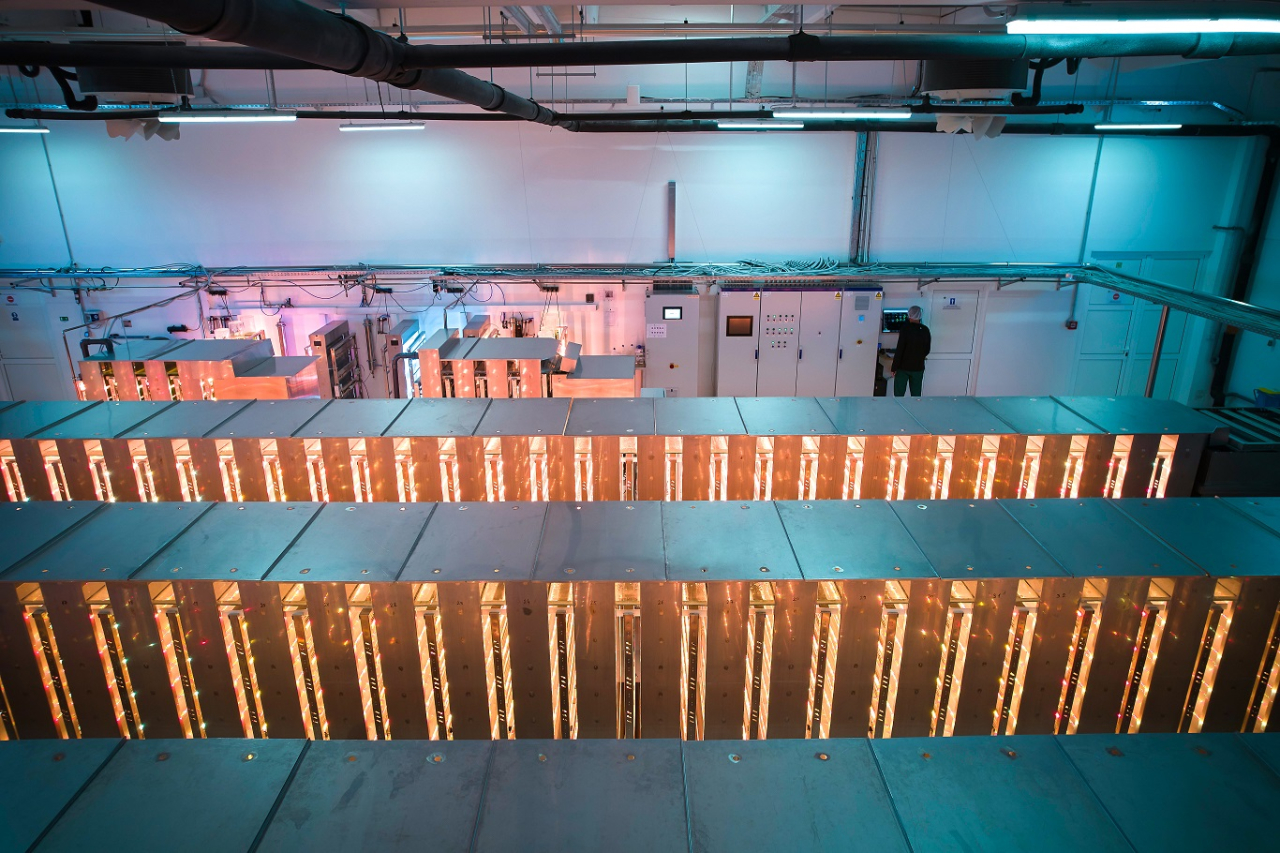

The air in the 600-square-meter building is pleasantly fresh. A reddish hue emanates from 11 steel and glass production lines where microalgae are thriving under LED lights. Borna Semenjuk dips a pH sensor into a 30-liter glass cylinder where algae are forming at the head of a big cultivation line. There’s a deep green shimmering through the glass. The production engineer points to a fine line of these single-cell organisms that have settled on the cylinder wall. “The algae are agglomerating because they don’t have enough carbon,” says the 26-yearold, who then glances at the display: 6.6 – indeed a bit on the low side. He presses a button on the wall, and fine CO2 bubbles effervesce through the cylinder.

While training as a food technologist a few years ago, Semenjuk learned how to banish algae. Now he does everything to help them proliferate. The right mix of nutrients, heat, illumination and CO2 keeps the microorganisms happy. In a matter of days, the chlorella in this glass cylinder will have multiplied to the point where they can be moved to intermediate storage in two progressively larger tanks and then decanted into one of the eleven 10,000-liter production lines.

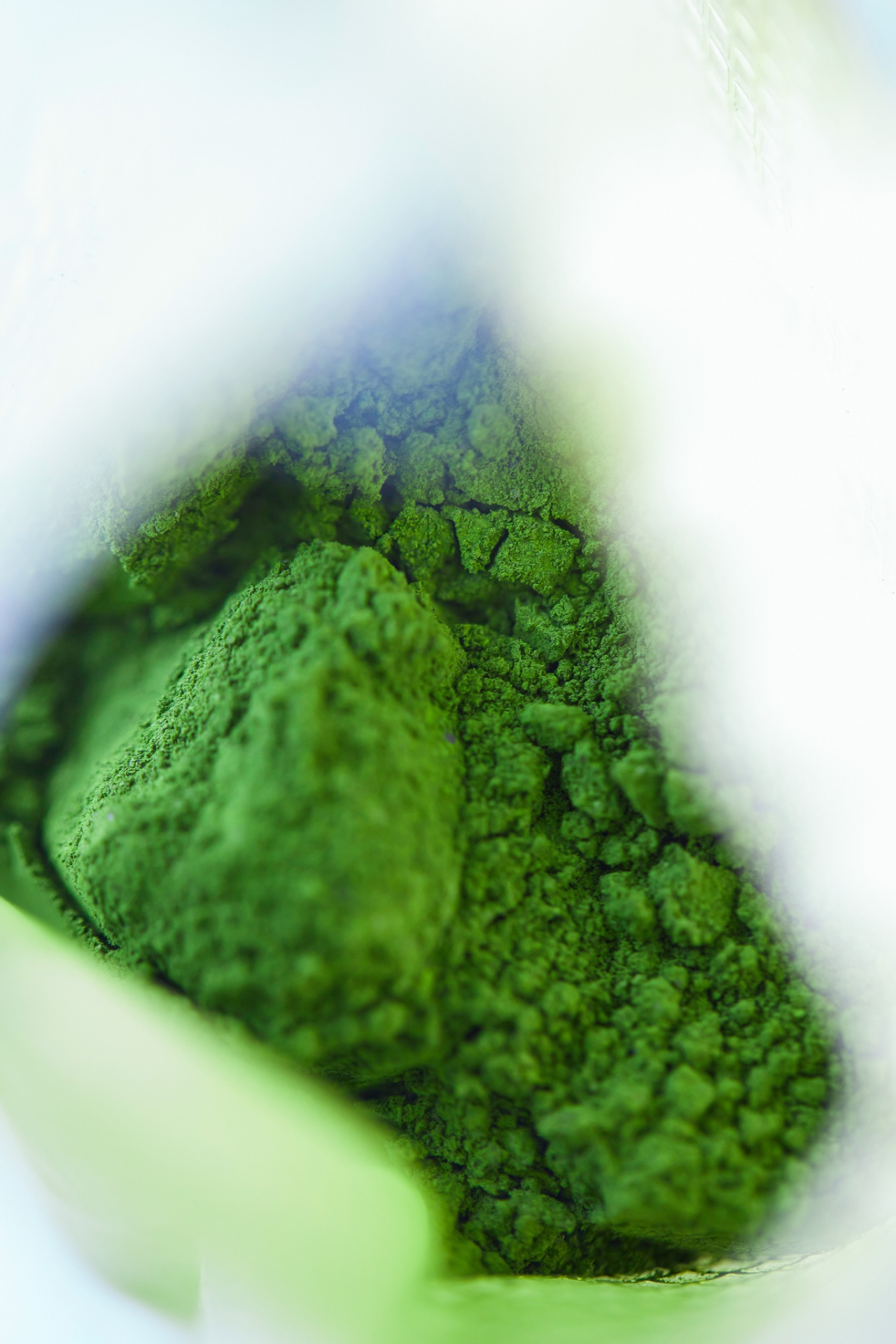

Semenjuk works for Phyox in Novska, which is a good hour’s drive from the Croatian capital Zagreb. Here the company has been manufacturing dry powder from chlorella algae for the pharmaceutical, cosmetics and food industries since late 2022. Phyox is involved both in customer business and on the development side. It aims to create ideal conditions for the industrial production of algae and plans to increase capacity twentyfold in the near future. This would make Phyox one of the world’s larger manufacturers, if not the largest, of high-purity microalgae powder.

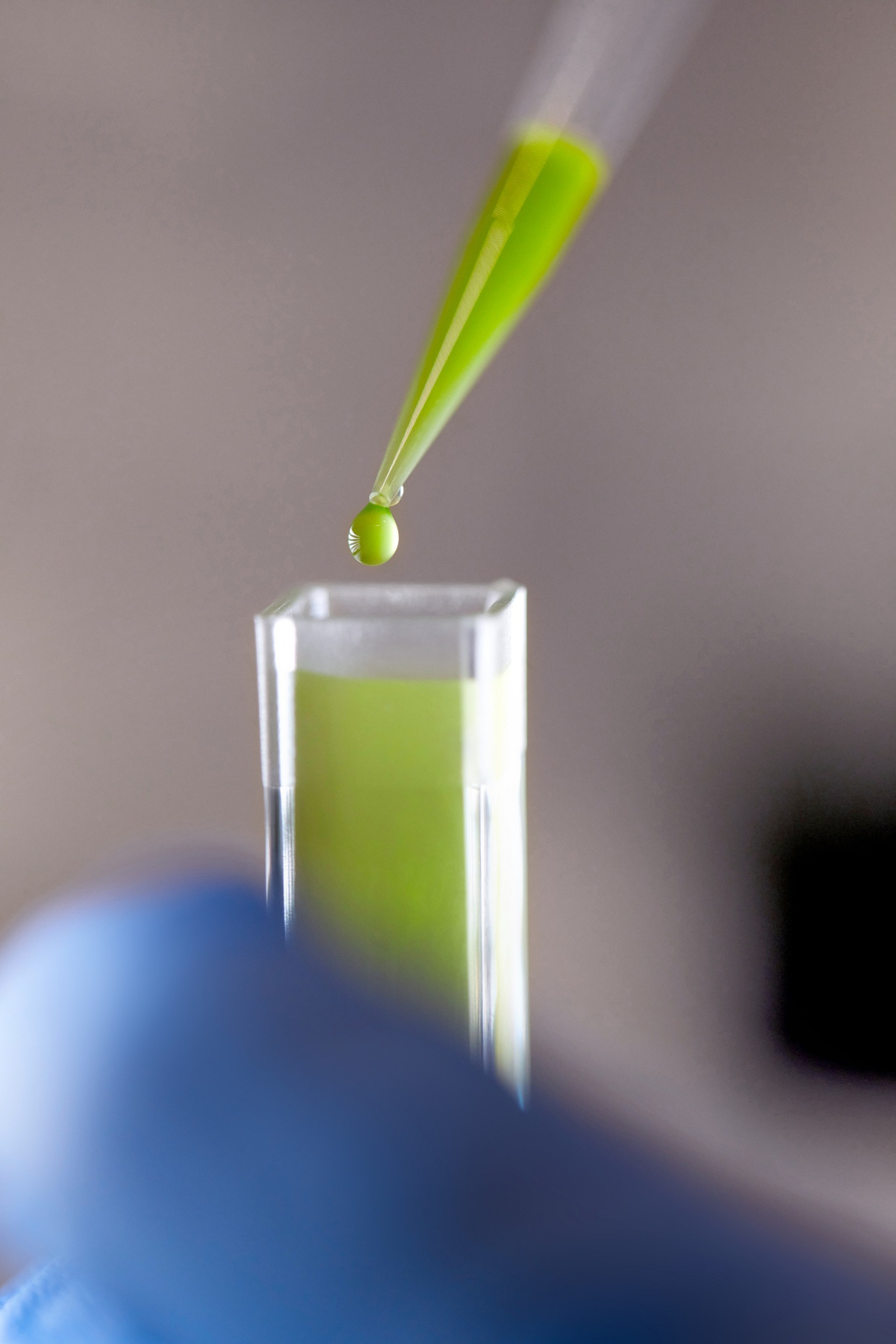

Microalgae such as chlorella can be used in food and personal care products and as a feedstock.

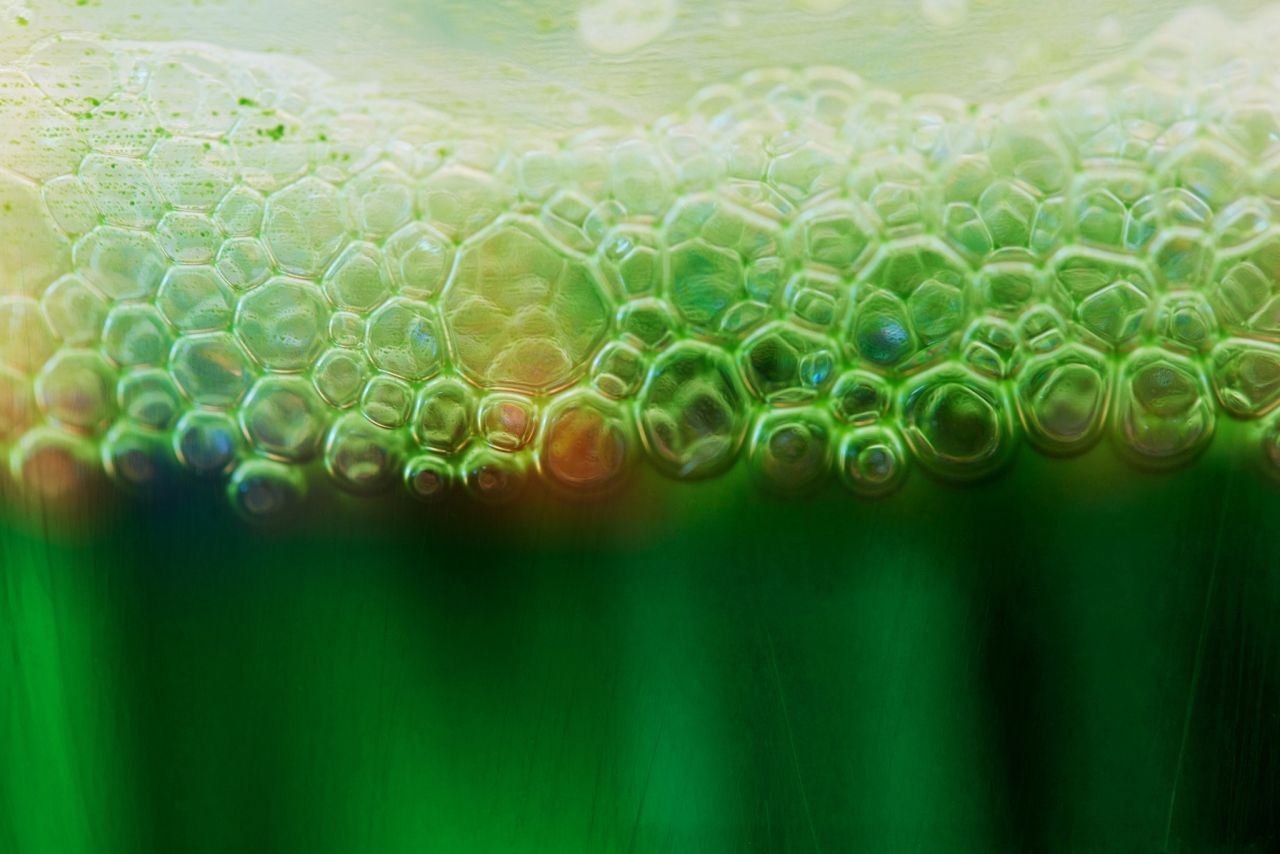

Thriving algae bind carbon dioxide and release oxygen.

Microalgae such as chlorella can be used in food and personal care products and as a feedstock.

SUSTAINABLE AND VERSATILE

The constituents of microalgae have already made them attractive to a wide range of industries as a superfood, an ingredient in cosmetic products, a binding agent, colorant or stabilizer. Algae can be found in gummy bears, ice cream and toothpaste. Pharmaceutical manufacturers make use of their blood-thinning properties, while the chemical industry uses them to produce environmentally friendly paint and fertilizer.

Algae may be set to play an even greater role in our lives. They contain the highest density of nutrients in the plant kingdom and multiply rapidly in a small space. With their proteins, vitamins and unsaturated fatty acids, they could help solve the problem of feeding the world’s population of more than eight billion and rising. Algae might enable the mass production of green plastic by the plastics industry, sustainable fabric by the textile industry, bioasphalt by the construction sector and other resource-saving materials. Medical research is also actively interested because of algae’s effectiveness against hazardous bacteria, viruses, cancer cells and possibly a plethora of diseases. Meanwhile, aviation fuel experts are investigating them as a source of biokerosene. Macroalgae with their high oil content make good candidates for a wide variety of biofuels; it is merely a question of cost and scalability.

Phyox CEO Bernd Herrmann opens the laptop in his office. Having started out in industrial plant engineering, three years ago he founded the company together with German and Croatian partners. Their original plan was to breed organic shrimp. “We were going to sell them to wholesalers,” he recalls and laughs. “That’s what got me into microalgae – as feed.” Herrmann, who is as visionary as he is down-to-earth, quickly realized that the green protozoa are much more interesting than shrimp. “Weight for weight, algae contain more omega-3 and omega-6 fatty acids than fish, more calcium than milk and masses of protein, as well as vitamins, trace elements and chlorophyll.” And to top it all, they are photoautotrophic organisms able to convert light into chemical energy, meaning they ingest carbon dioxide and excrete oxygen as a waste product. “Our 600-square-meter production plant has the same oxygen output as 40 hectares of forest,” says Herrmann, which explains why the air in the building is so good. That fact also attracts investors on the lookout for carbon-offsetting options.

Phyox produces algae in closed bioreactors that are unaffected by external factors.

The LED light intensity and pulse rate are precisely tailored to the needs of the algae.

Under controlled conditions, the chlorella algae grow three to five times as big as in a natural environment.

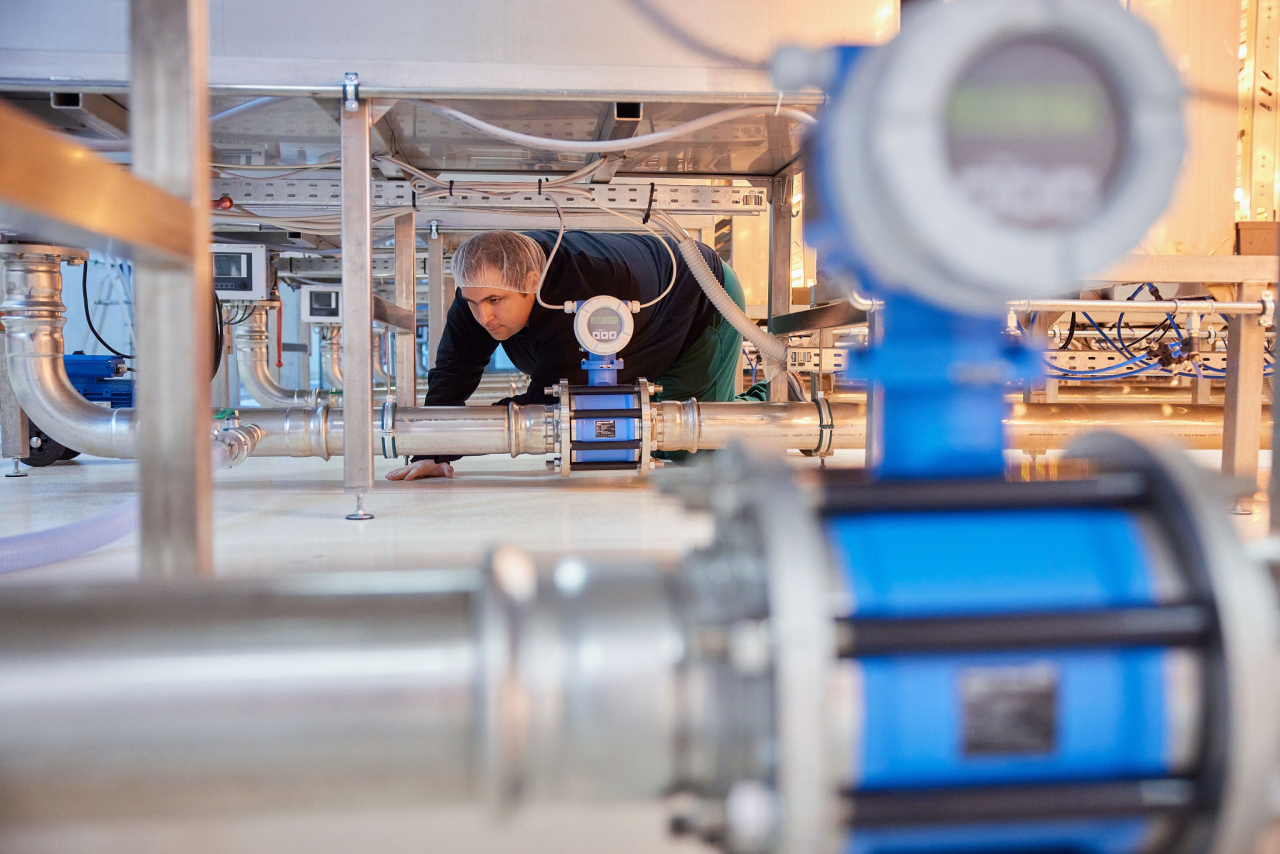

Measuring technology monitors processes and conditions at the highly automated plant in Croatia.

“Phyox’s visionary ideas fascinated me from the start.”

Christian Fischer

technical sales manager, Endress+Hauser Germany

“Our 600-square-meter production plant has the same annual oxygen output as 40 hectaresof forest.”

Bernd Herrmann

CEO of Phyox

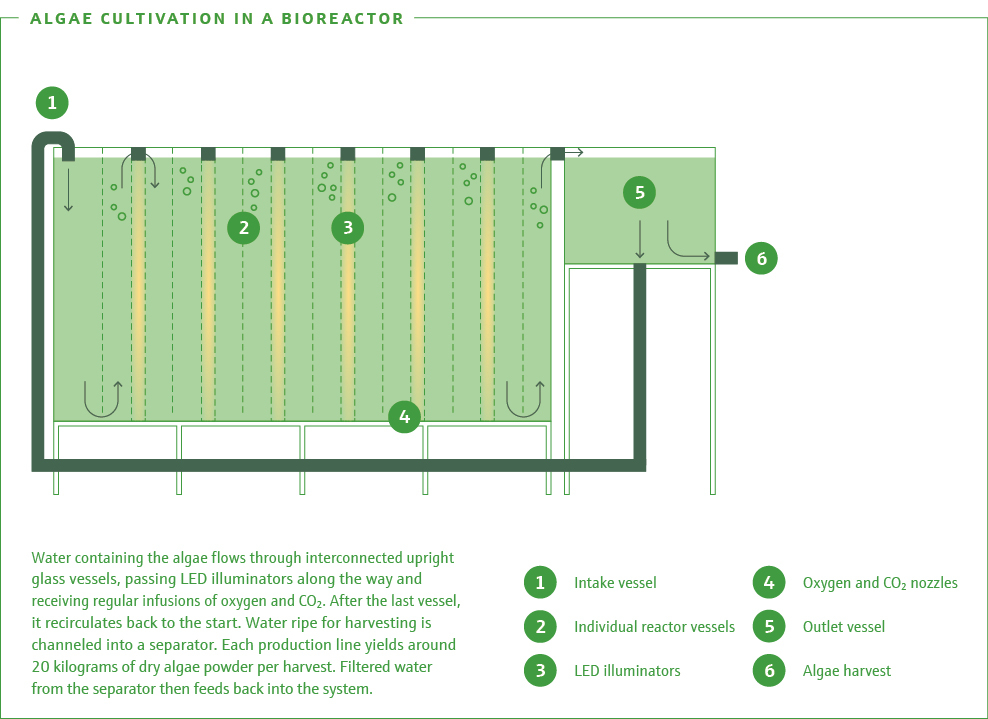

BIOREACTORS DEVELOPED IN-HOUSE

While other producers grow algae outdoors in open tanks or closed glass tubes, Phyox has moved its manufacturing to proprietary indoor bioreactors. Water containing the algae meanders past LED strip lighting with an intensity and pulse rate precisely tailored to the needs of cultivating the chlorella algae. Fine nozzles on the bioreactor floor pump in a blend of oxygen and carbon dioxide, ensuring even distribution of warmth and nutrients while steadily propelling the liquid forward. At the end of the line, algae in suspension are pumped back to the start and continue repeating their transit until a turbidity sensor indicates that it is time for the harvest. A separator then extracts algae from the water and the permeate – the filtered water – flows back to the line, where it is manually replenished with fresh stock.

“Phyox’s visionary ideas fascinated me from the start,” says Christian Fischer of Endress+Hauser Germany. “This kind of production is not dependent on the sun or the seasons. Nor are there any contamination risks, unlike with open tanks,” adds the technical sales manager, who has been helping to oversee the project since its inception. So Phyox can continue manufacturing 24 hours a day, 365 days a year in a highly controlled environment, he says. Along with process instrumentation, Endress+Hauser also supplied the automation solution including remote access.

Bernd Herrmann, CEO of Phyox

Plant automation ensures consistent quality and the highest possible yield.

“Control and sensor technologies lie at the heart of it all,” says Bernd Herrmann with conviction. In Endress+Hauser, he has found a partner that not only implements his ideas but is also willing to dig down into the complex subject matter. “Algae are highly sensitive creatures, so you need to develop a precise understanding of them.” Any tiny shift in things such as flow rates, water parameters or illumination intensity and color will have consequences. That’s why the water is constantly monitored for flow and level, turbidity, pH and conductivity. Based on those measurements, nutrients or water are dosed automatically. Memosens technology allows the same analysis techniques to be used in manufacturing and in the laboratory.

Automation plays its part by ensuring high quality of production. “Should bacteria start spreading among the algae at three in the morning, we need to respond immediately,” Herrmann stresses. In such events, the Phyox plant automatically switches to ultrafiltration and, if necessary, rescues the algae by initiating the harvesting process.

2tonnes

of CO2 go into producing 1 tonne of algae.

Each production line yields around 20 kilograms of dry algae powder per harvest.

If customers want it, Phyox can produce algae with very specific properties.

Laboratory work delivers new findings on the largescale cultivation of algae.

ALGAE EXTRACTS MADE TO ORDER

All this allows Phyox to do more than just make a high-purity product and maximize production yields. “We can also cultivate microalgae with very specific properties for precise customer requirements.” Indeed, the focus has long since shifted away from algae as a straightforward generic product and toward individual extracts such as carotene and lutein. Adding just a single gram of phosphate to the nutrient mix can make the difference here. “Every measurement value is a field of research in its own right,” says Herrmann, who aims to take the facility to the next level by creating a fully automated and digitalized ‘plant 5.0’ for up to 15 different varieties of microalgae. The plan is also to use artificial intelligence to ensure optimum cultivation conditions.

Algae are both sensitive and highly diverse organisms. For example, while chlorella must be vigorously agitated to prevent adhering to the glass cylinder wall, dunaliella drift freely through the water. Some varieties of algae need a lot of light, others prefer it a little darker. Herrmann regrets the lack of support from academic research: “Most of the work to date has been with small quantities, so it’s not particularly useful for volume production.” With its planned expansion, Phyox therefore wants to build a campus for algae research. The goal is to develop the largest algae cultivation plant in the world with scientifically based, highly automated production.

The fact that this is a realistic vision is evident from the interest shown by investors as well as industrial and research partners worldwide. And the chlorella algae at Phyox give a helping hand too. In a natural habitat, the organisms reach around five to eight micrometers in diameter. But at Phyox, they grow three to five times that size. “Without losing any of their constituents,” says Herrmann. “And right now, we only know a fraction of what there is to learn about algae,” he adds with a smile.

Published 29.11.2023, last updated 25.01.2024.

Dive into the world of the process industry through new exciting stories every month with our «changes» newsletter!