Delivered

Around 80 percent of all products move along global value chains that themselves provide a livelihood for more than 450 million people. Yet their delicate links tend only to be discussed when they are disturbed. It’s time to take a look at this fascinating world.

World’s oldest supply chain?

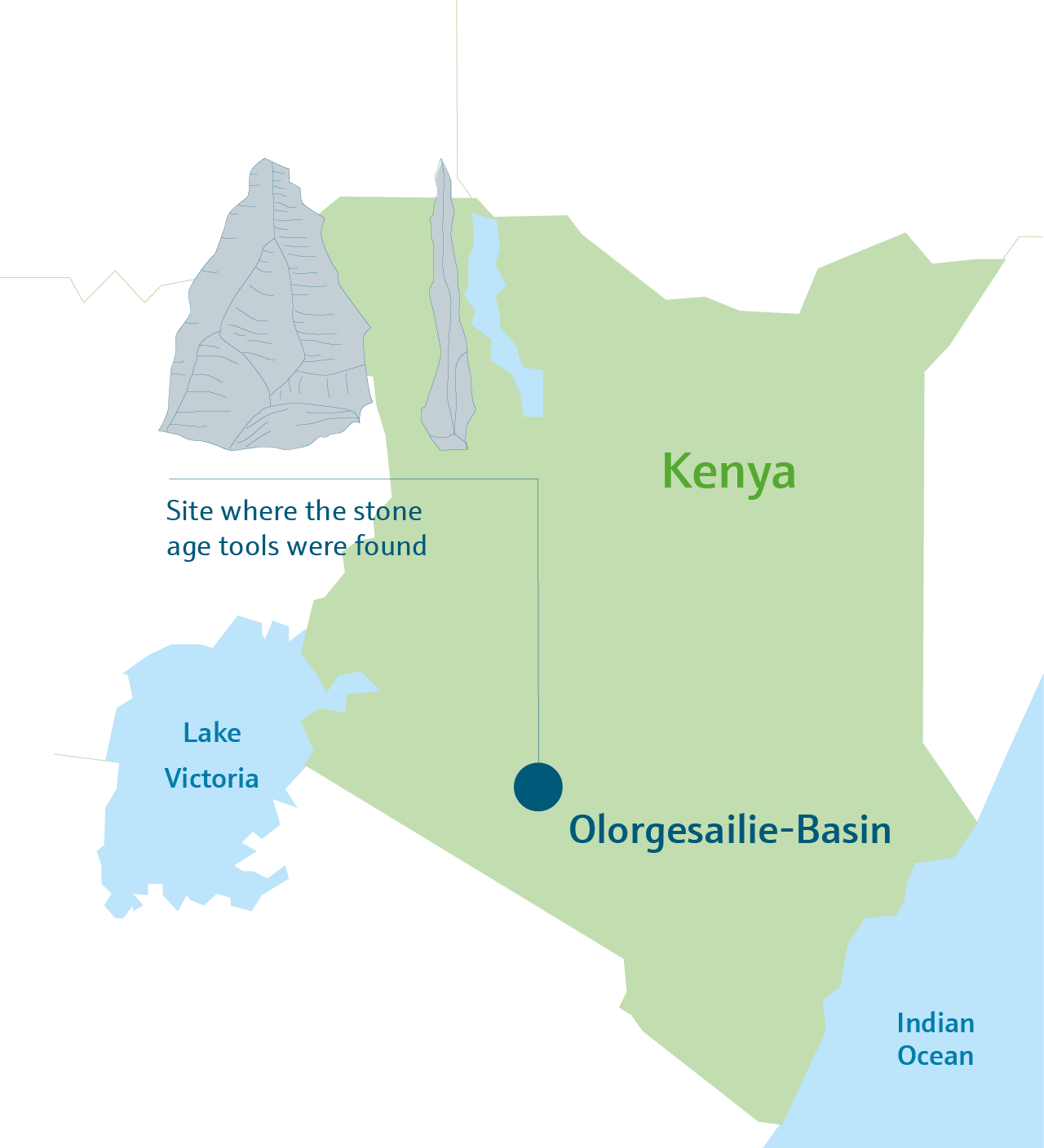

More than 300,000 years ago, people in the Olorgesailie Basin in southern Kenya advanced from primitive hand axes to making tools from obsidian, a volcanic rock glass. American paleoanthropologists working in the area have found such tools in large quantities, even though the obsidian sources lie up to 100 kilometers away, with many mountains in between. For this reason, researchers have ruled out the possibility that the tool makers ‘commuted’ to fetch their own raw materials. Instead, these were likely imported via a chain of people living in different localities, presumably in exchange for other goods. The obsidian finds from Olorgesailie are thus considered to be the world’s oldest evidence of long-distance trade, dating back 80,000 to 100,000 years earlier than other examples.

From local to global

![]()

Pre-1900, supply chains were mainly organized at a local and regional level.

![]() In the early 20th century, expansion of the rail network, the growth of steam shipping and the increased use of trucks meant that distances shrank. Pallets and forklift trucks found their way into logistics.

In the early 20th century, expansion of the rail network, the growth of steam shipping and the increased use of trucks meant that distances shrank. Pallets and forklift trucks found their way into logistics.

![]()

The mid-1950s saw the earliest containers come into use, which were standardized soon after.

![]() The mid-1960s saw the advent of computers in warehousing. The first real-time warehouse management system arrived in the 1970s, with barcodes replacing manual entry of product numbers.

The mid-1960s saw the advent of computers in warehousing. The first real-time warehouse management system arrived in the 1970s, with barcodes replacing manual entry of product numbers.

![]() 1983 marked the coining of the term ‘supply chain management’. PCs and software such as spreadsheets and route planners made supply chain management increasingly efficient.

1983 marked the coining of the term ‘supply chain management’. PCs and software such as spreadsheets and route planners made supply chain management increasingly efficient.

![]() In the future, artificial intelligence and machine learning are set to improve order management. Transparency in supply chains is proving an increasingly prominent factor for success.

In the future, artificial intelligence and machine learning are set to improve order management. Transparency in supply chains is proving an increasingly prominent factor for success.

Humming experts

Bees are born logisticians in that they communicate precisely and act intelligently in a swarm. Say a scout bee discovers a feeding site: Back at the hive, it will perform a special dance to tell the forager bees about it. The dance communicates the exact location of the site as well as the quality and yield of the food source. Such information facilitates efficient transport of food material and thus ensures survival of the colony.

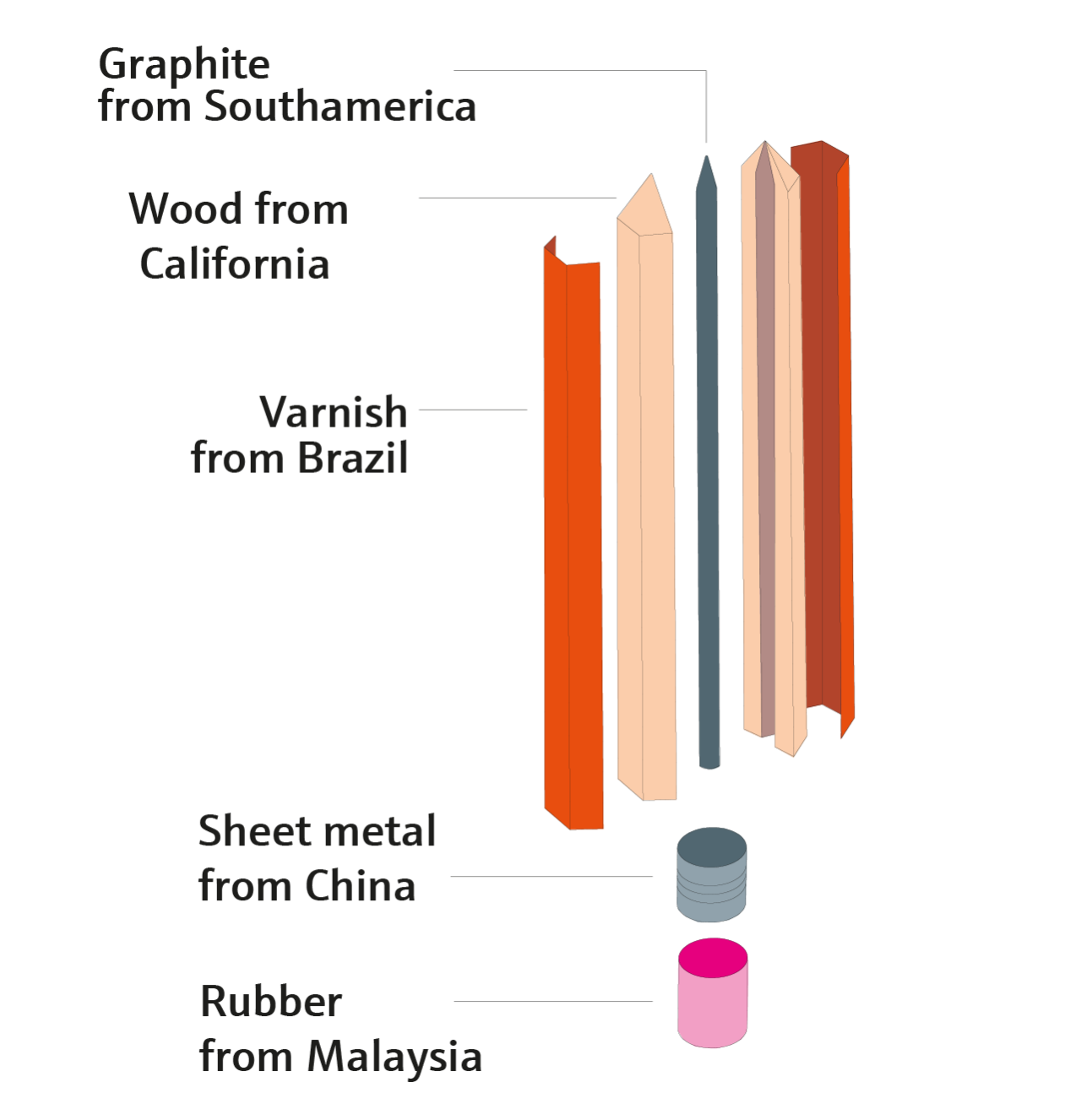

The miracle of the pencil

In summing up the invisible complexity behind everyday products, Milton Friedman famously said, “Nobody knows how to make a pencil.” The US Nobel Prize winner made highly entertaining use of the pencil example in a 1980s TV lecture to explain just what the economy is capable of. Making a pencil entails mining graphite, extracting rubber and felling wood in various regions of the world. Felling trees requires chainsaws, which in turn require steel, produced from iron ore as the main raw material, and so on. Summing up, there are countless steps and thousands of people involved in making something as seemingly simple as a pencil. That humble object is, in fact, a tour de force of global cooperation.

Bottlenecks in world trade

According to credit insurance group Allianz Trade, the almost week-long blockage of the Suez Canal by a container ship that ran aground damaged global trade to the tune of US$6–10 billion a day. As many as 200 ships were backed up at the head of the canal in March 2021, with the result that raw materials and semiconductors failed to reach their destinations on time. The consequences of a blockade of the Strait of Hormuz would be even more extreme. Around 30 percent of the world’s oil production is shipped through the 50-kilometer-wide strait between the Persian Gulf and the Gulf of Oman from suppliers such as Iraq, the United Arab Emirates and Kuwait. A fifth of global liquefied natural gas supplies also pass through the strait.

The optimal pub crawl

The traveling salesman problem is a classic logistical conundrum. Someone needs to travel through many places, before ultimately returning to their starting point. The aim is to find the shortest route. If the salesman needed to visit just 10 cities, he could choose from 181,440 different round trips. But the conundrum grows more extreme still: In 2018, researchers at Cook University of Waterloo in Canada determined the shortest route to visit all 49,687 pubs in the United Kingdom. The sheer number of options meant that algorithms and artificial intelligence alone were not enough; manual work and mathematical trial and error were crucial in coming up with an answer. It turns out that the optimal itinerary covers around 64,000 kilometers.

The measure of all things

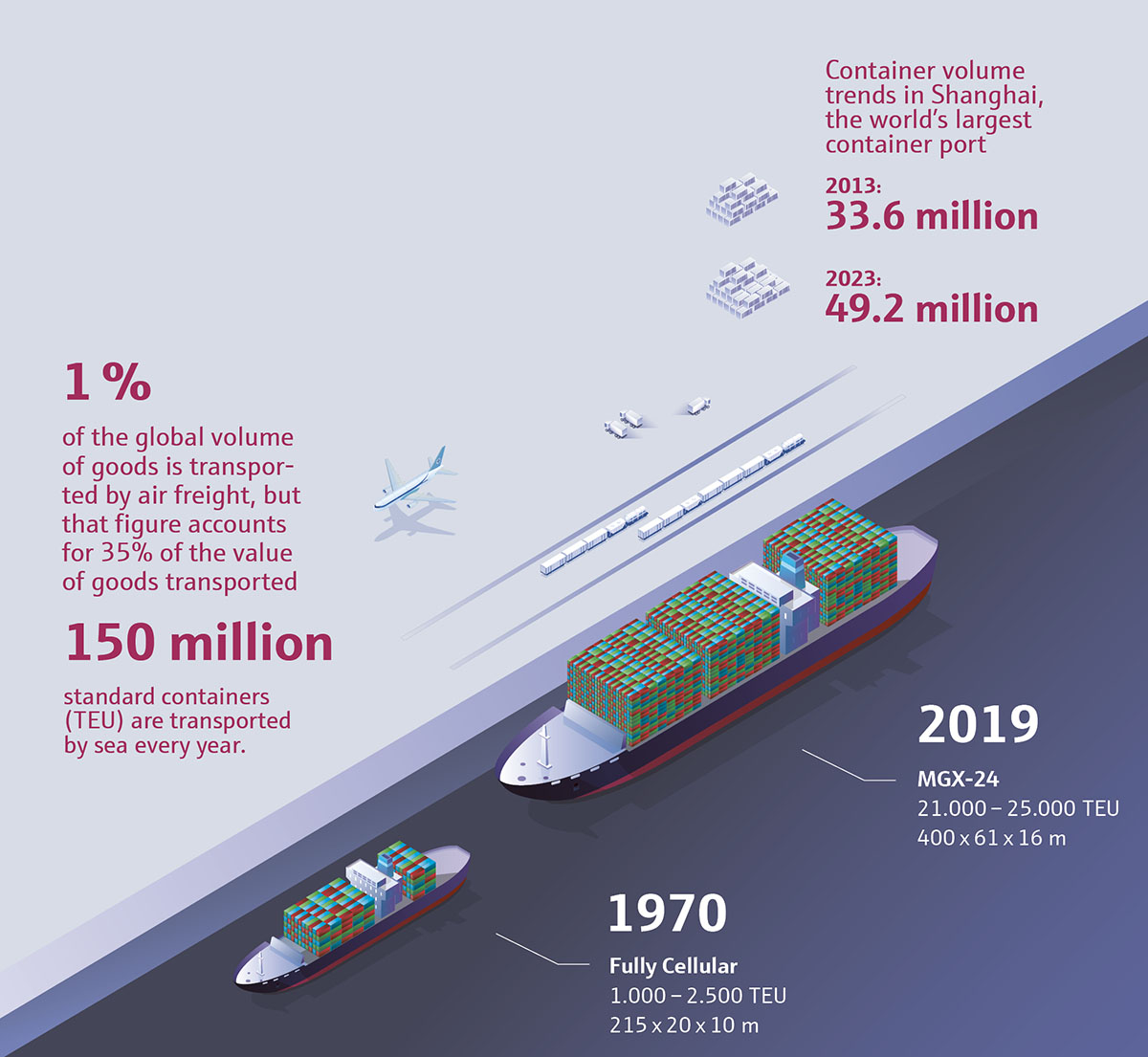

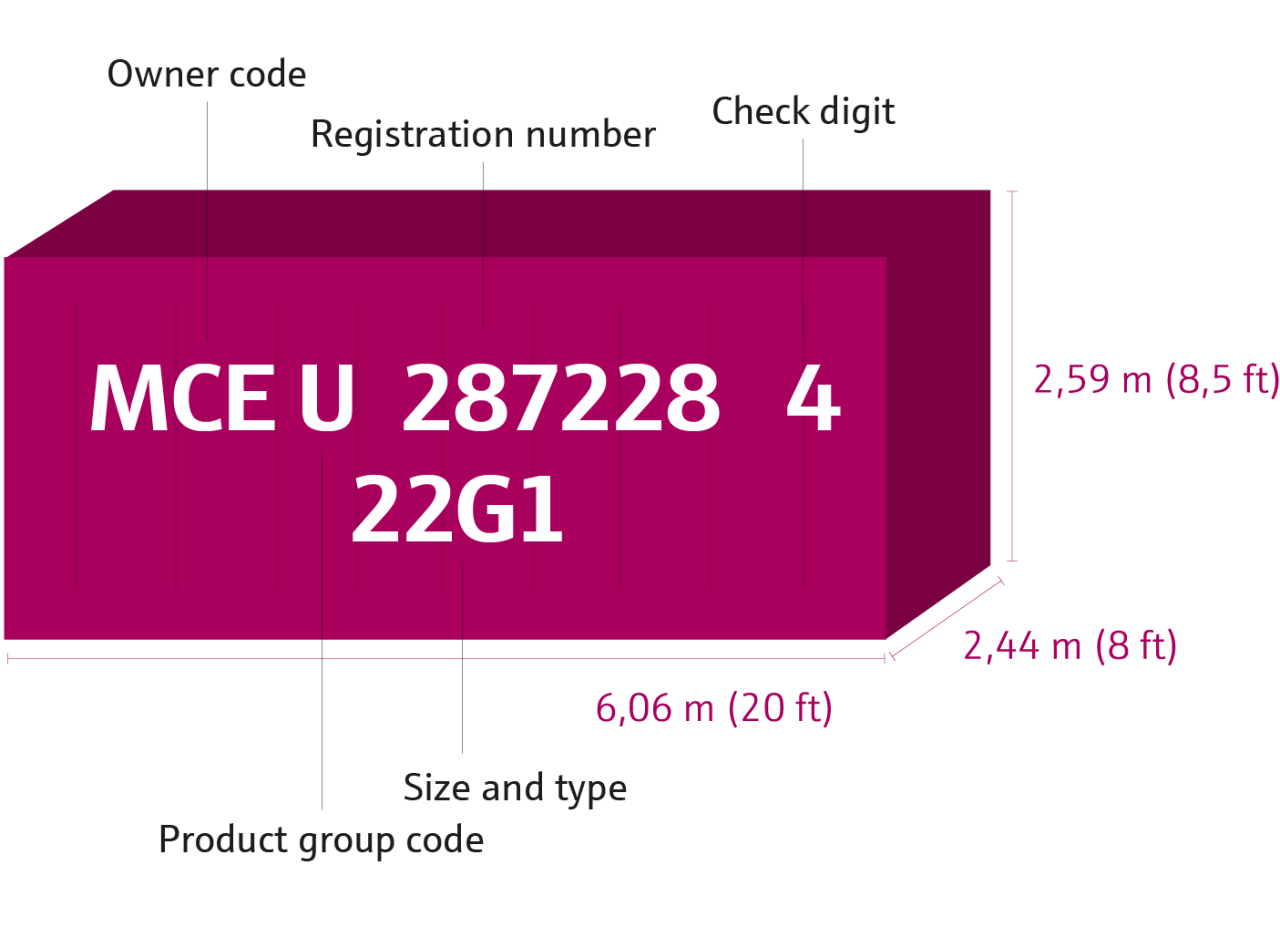

The 20-foot standard container (TEU)

Think of supply chains, and shipping containers automatically come to mind. For good reason, too: almost all trade goods travel around the world in these cuboid receptacles. Standardized container sizes make them easily stackable for optimal use of a ship’s carrying capacity. To transport more and more containers at ever lower costs, container ships have grown into ocean-going giants over time. Their load volume has increased tenfold over the space of 50 years. As such, they are a major driver of global trade.

So that no container goes astray on its travels, each has its own unique identifier, issued by the Bureau International des Containers et du Transport Intermodal.

Published 04.11.2024, last updated 12.11.2024.

Dive into the world of the process industry through new exciting stories every month with our «changes» newsletter!