Circular polymers

Covestro has made circular economy a guiding principle – and is showing the way forward in the plastics industry by fully committing to it. A look at the latest developments from Leverkusen, Germany.

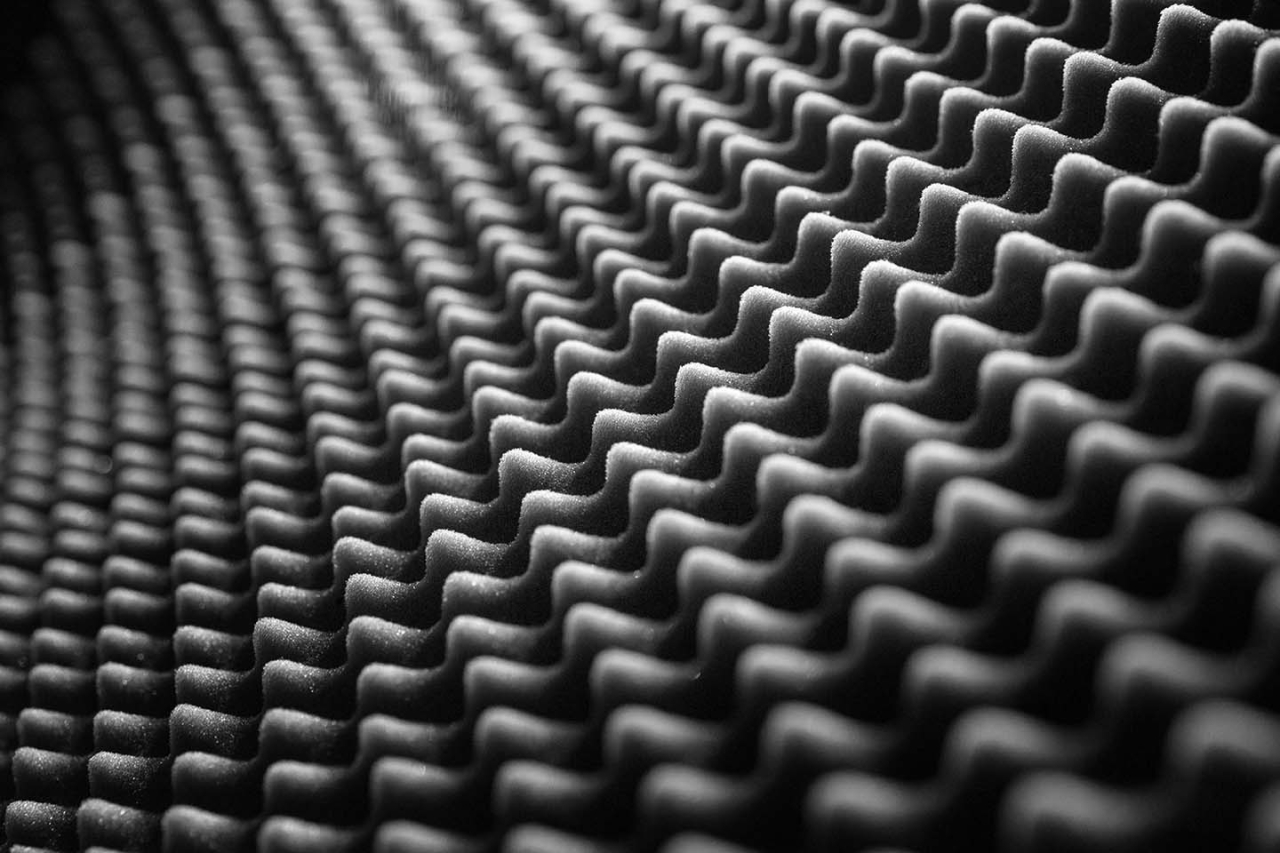

Polyurethanes are ubiquitous. For the past 90 years, these all-rounders of the plastics world have been bringing comfort, stability and weather-proofness to our lives. As liquid coatings, they impart hard-wearing surface finishes to cars and floors. In the form of adhesives, they hold shoes and books together. The synthetic polymers are also essential to the furniture industry, in the form of flexible foams used for upholstery and mattresses. They are in rigid foams too, the kind that thermally insulate refrigerators and millions of buildings, thus boosting energy efficiency and making a significant contribution to climate protection.

IN THE MIDST OF CHANGE

Yet polyurethanes have some catching up to do in terms of their own sustainability. Like almost all of the world’s 414-million-tonne annual plastics output, they are generally made from petroleum products – a pathway that generates CO2 emissions and drives climate change. And, at end of life, they wind up in landfills or incinerators. According to the OECD, only nine percent of the world’s plastic waste is recycled. But things are changing. “More and more chemicals companies are starting to rethink polymers. The industry is in the midst of a fundamental transformation process,” says Thomas Pellender, technical sales manager for the chemical industry at Endress+Hauser Germany. The pioneers here include Covestro, one of the world’s leading manufacturers of high-quality plastics and plastics intermediates. “The circular economy has been a guiding principle for us since 2019, and we are fully committed to it. We can’t achieve climate neutrality without circularity,” explains Dr Thorsten Dreier, chief technology officer at Covestro.

Covestro’s aim with its strategic program is to transition the production of plastics and their chemical constituents to environmentally friendly and climate-neutral alternatives wherever possible. Hence, the company makes increasing use of bio-based raw materials and renewable energy in its production processes. Alongside this, it is developing innovative, energy-efficient technologies to optimize the mechanical and chemical recycling of end-of-life products and unavoidable waste. The idea is that products and processes should be circular by design. Thorsten Dreier: “In all areas, we are cooperating with actors from across the value chain and the science community and forging new partnerships to find solutions that are best for the circular economy.”

1

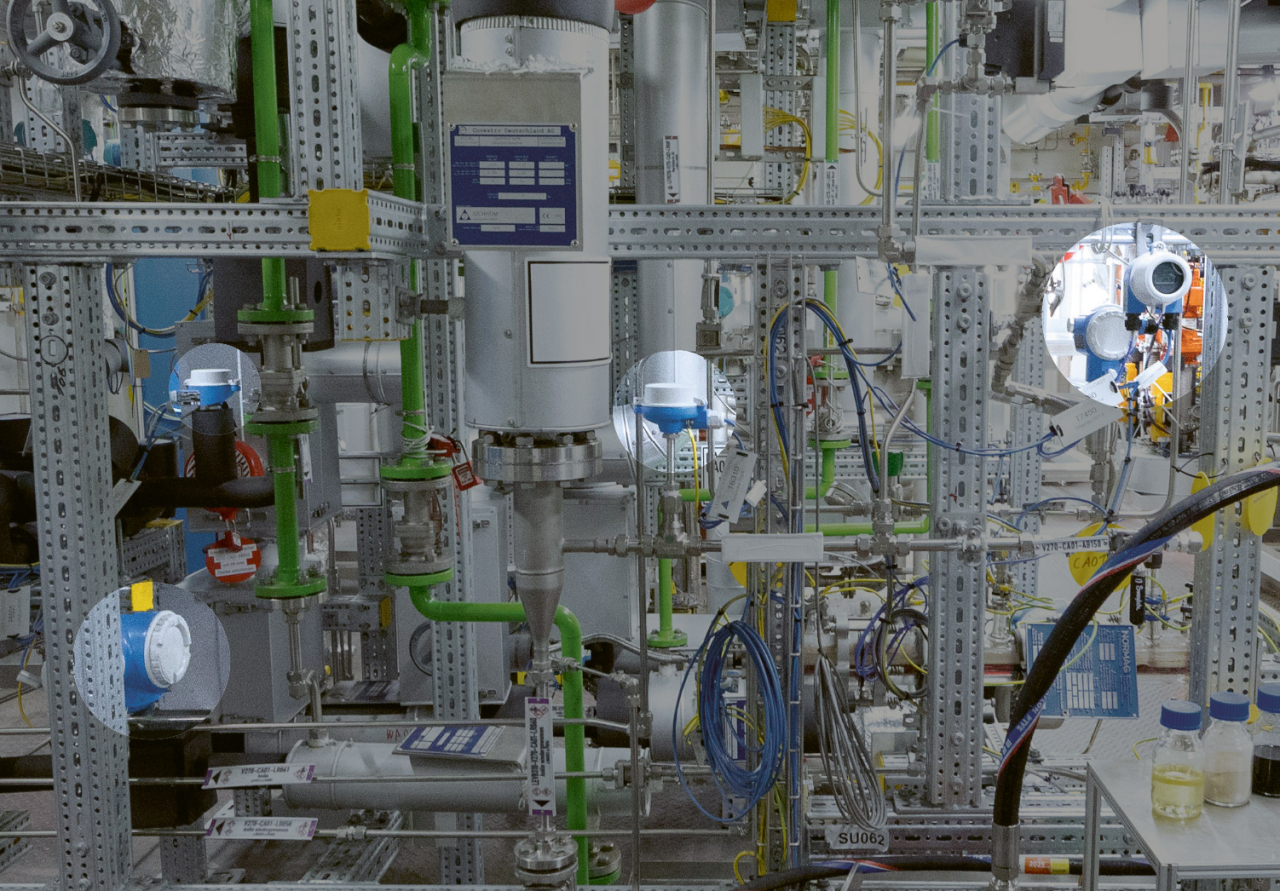

Covestro develops new technologies at its headquarters in Leverkusen, Germany.

2

At a pilot facility, the company pioneers the production of bio-based aniline.

3

The innovative process is optimized with the aid of measurement technology.

BUILDING BLOCK OF THE FUTURE

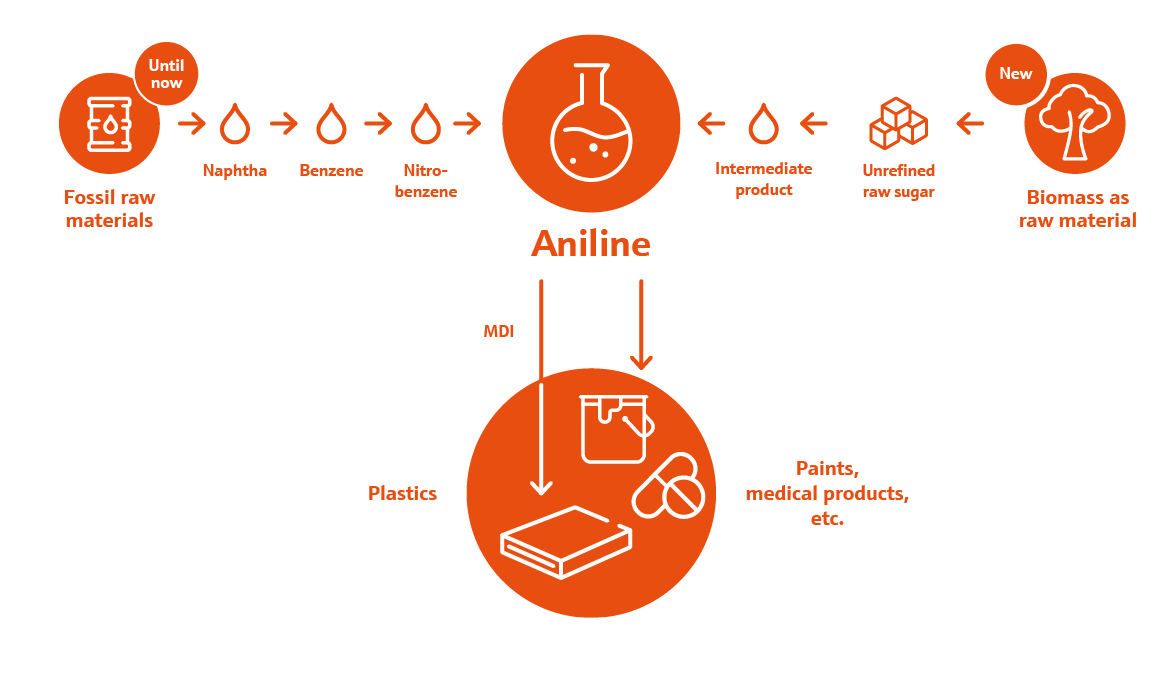

The fruits of these efforts can be seen at Covestro headquarters in Leverkusen, Germany. On the factory campus there is a pilot facility with a vast array of reactors, columns, vessels and heat exchangers that occupies no fewer than four levels of an expansive laboratory and testing center. The facility, a world first, also has 600 meters of pipework as well as over 150 measuring points and sensors – many of them made by Endress+Hauser. The colorless liquid produced by this facility may in future be instrumental in expediting the transition to circularity – for the chemicals and plastics industry generally, and for Covestro in particular. “We have pioneered a process for producing aniline, one of our most important precursors, that uses plant biomass instead of petroleum-derived benzene,” explains project lead Thomas Vössing.

Covestro produces about a million tonnes of this organic compound annually, or about one sixth of worldwide output. “We use the aniline to produce MDI,” Thomas Vössing explains. MDI stands for methylene diphenyl diisocyanate – one of the main chemical building blocks used in the manufacture of rigid polyurethane foam. Covestro’s investment in the pilot plant runs into the single-digit millions of euros. The plant is the culmination of eight years of research conducted in partnership with RWTH Aachen and the universities of Düsseldorf and Stuttgart, also supported by government funding. “Commissioning the pilot plant was a major milestone,” Vössing says. “The biggest challenge with this project was to develop a holistic process concept from scratch and then translate it to a technical scale. That involved designing items of equipment that had never been built before.”

Bio-based aniline is produced in a series of steps. To begin with, a customized bacterium is used to ferment plant-based industrial sugar into an intermediate product that is isolated and then, in a following step, catalytically converted to aniline. “Once purified through distillation, this product can be used as a bio-based ‘drop-in’ alternative to petro-based aniline – the two are chemically identical,” explains Thomas Vössing.

9%

of the world's plastic waste is recycled, according to the OECD

“Measurement technology provides the basis for deep understanding of processes and is therefore fundamental to the development of new processes.”

Sebastian Mahler,

head of process control technology, Covestro

150

measuring points and sensors feature in Covestro’s pilot plant for bio-based aniline.

CLOSE PARTNERSHIP

That the pilot plant’s process monitoring systems include Endress+Hauser measurement technology almost goes without saying. “Endress+Hauser is one of the suppliers with whom Covestro has a long-standing partnership,” says Sebastian Mahler, head of process control technology at Covestro. Indeed, it is a partnership that goes back decades. Covestro was created from the spin-off of Bayer AG’s plastics division in 2015 and previously did business as Bayer MaterialScience. A supplier agreement with Bayer concluded back in 2003 means that Covestro uses Endress+Hauser instruments as standard in its plants all over the world. “Our relationship with Covestro is very close and reliable at all levels, from service technicians to senior leadership. We get onboarded in their projects at an early stage. This means we are in dialog with their technical people and can recommend the best sensors for their needs and advise them on systems design,” explains Endress+Hauser technical sales manager Thomas Pellender.

Covestro’s Sebastian Mahler agrees: “On the technical side, this is a partnership between equals. Endress+Hauser, like few other companies we deal with, is willing to dive deep into the special technical requirements of our processes to see if they can be realized. We and our counterparts are mutually supportive and can also provide input to further developments in both organizations.” At Covestro, a prime function of measurement technology is to keep plant and equipment operating reliably and efficiently, which in turn reduces consumption of energy and raw materials and minimizes waste. “Measurement technology is fundamental to the development of new processes,” Mahler says. “It provides the basis for deep understanding of processes and for determining and calculating scale-up factors.” High-precision measurements enable Covestro to test, understand and optimize new technologies so that it can progressively scale them up to the point where they can be used for full-fledged industrial production.

THE PATH TO CIRCULARITY

Covestro has been fully committed to the circular economy since 2019. Its circularity strategy for effecting this transformation and achieving its sustainability goals rests on five pillars.

1

Covestro uses aniline to make a raw material for insulation panels.

3

The company also aims to make foam materials more sustainable.

2

At a special competence center, Covestro conducts research into biotechnology approaches.

4

Covestro is looking at ways of recovering the constituents of flexible foams from old mattresses using chemical recycling.

414million

tonnes of plastics are produced worldwide every year.

INNOVATION IS KEY

Several instances of such upscaling are currently under way on the Covestro factory campus. As an example, a pilot plant for bio-based hexamethylene diamine (HDMA), a precursor for liquid coatings and adhesives, has been operating since 2022. Covestro developed the process technology for this in partnership with US biotech company Genomatica. “Whatever the project, partnerships are important for us because synergizing specialist expertise brings us closer to our goals,” says Thomas Vössing. The same is true for the 20-plus projects where Covestro is researching novel recycling methods. “Alongside research into raw materials from new, bio-based sources, we are vigorously driving the development of these innovative recycling technologies. Our vision is to become fully circular and climate neutral, and we are pursuing all avenues for innovation that can bring us closer to this goal,” explains Thorsten Dreier, Covestro’s chief technology officer. “Recycling has the potential to take us a long way towards closing the loop and transforming waste into raw materials that we can use in production.”

In another pilot plant, Covestro and its partners have achieved an initial breakthrough in chemical recycling. The plant recycles polyurethane flexible foams from used mattresses a worthwhile endeavor, considering that each one contains on average 15–20 kilograms of the material. The uniqueness compared with other chemical methods is that the Covestro chemical recycling technology, Evocycle CQ, is able to recover both main constituents of polyurethane – polyol and the precursor to diisocyanate – at high levels of quality and purity. In contrast, Covestro’s enzymatic recycling technology is still in early-stage development. This biotechnological approach uses enzymes to decompose plastics into monomers which can then be used for producing new plastics of equivalent quality to virgin material. The advantage of enzymatic recycling is that it takes place at very mild temperatures and produces few to no by-products. As such, it brings the chemicals industry a whole lot closer to the closed-loop systems of nature, where there is no waste and everything is recycled.

While these are important milestones, Covestro still has a long way to go before it achieves full circularity across its entire production landscape for plastics and their constituents. But for CTO Thorsten Dreier, one of the people tasked with championing the circular economy strategy at Covestro, these and other key milestones are cause for confidence: “We are making new advances in all areas almost on a daily basis. That having been said, we’re still a long way from reaching our goal.”

Chemicals from plant sources

Production of the basic chemical aniline is now possible without the use of crude oil or other fossil raw materials – thanks to a research breakthrough by Covestro.

Published 21.05.2025, last updated 12.06.2025.

Dive into the world of the process industry through new exciting stories every month with our «changes» newsletter!