Singular excellence

Endress+Hauser has adapted Coriolis technology to be viable in single-use applications. The newly developed Proline Promass U 500 measures flow rates with precision and efficiency to match – as well as being ideally built for subsequent recycling.

$ 38.8billion

is the projected size of the market for single-use biotechnology in 2030. More aggressive estimates put the figure at over 80 billion US dollars. The 2024 figure already stands at around 18 billion US dollars.

Biotech is a rapidly growing market: Using genetically modified cells taken from microorganisms to produce drugs and vaccines is an enabler for new therapies to tackle many serious diseases. The boom in biotech is also changing production techniques. The trend is for smaller batches made using more compact and flexible systems, and increasingly with a continuous process. Absolute purity is a must when working with sensitive cell cultures: “The slightest contamination can ruin an entire batch,” says Samuel Neeser, Coriolis product manager at Endress+Hauser.

In production facilities built around a multi-use design, all components that come into contact with process media need thorough cleaning and sterilization every time. That involves aggressive acids and a lot of energy for generating steam. “Even then, the risk of contamination is still not zero,” says Samuel Neeser. Hence a clear move to single-use technology: Worldwide, one in every two biotech products is now manufactured like this, with every component contacting a medium only once.

SOPHISTICATED DESIGN, HIGH-QUALITY MATERIALS

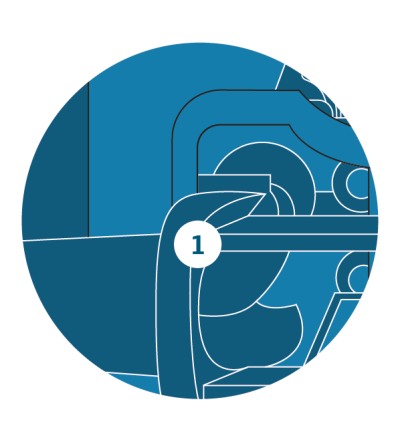

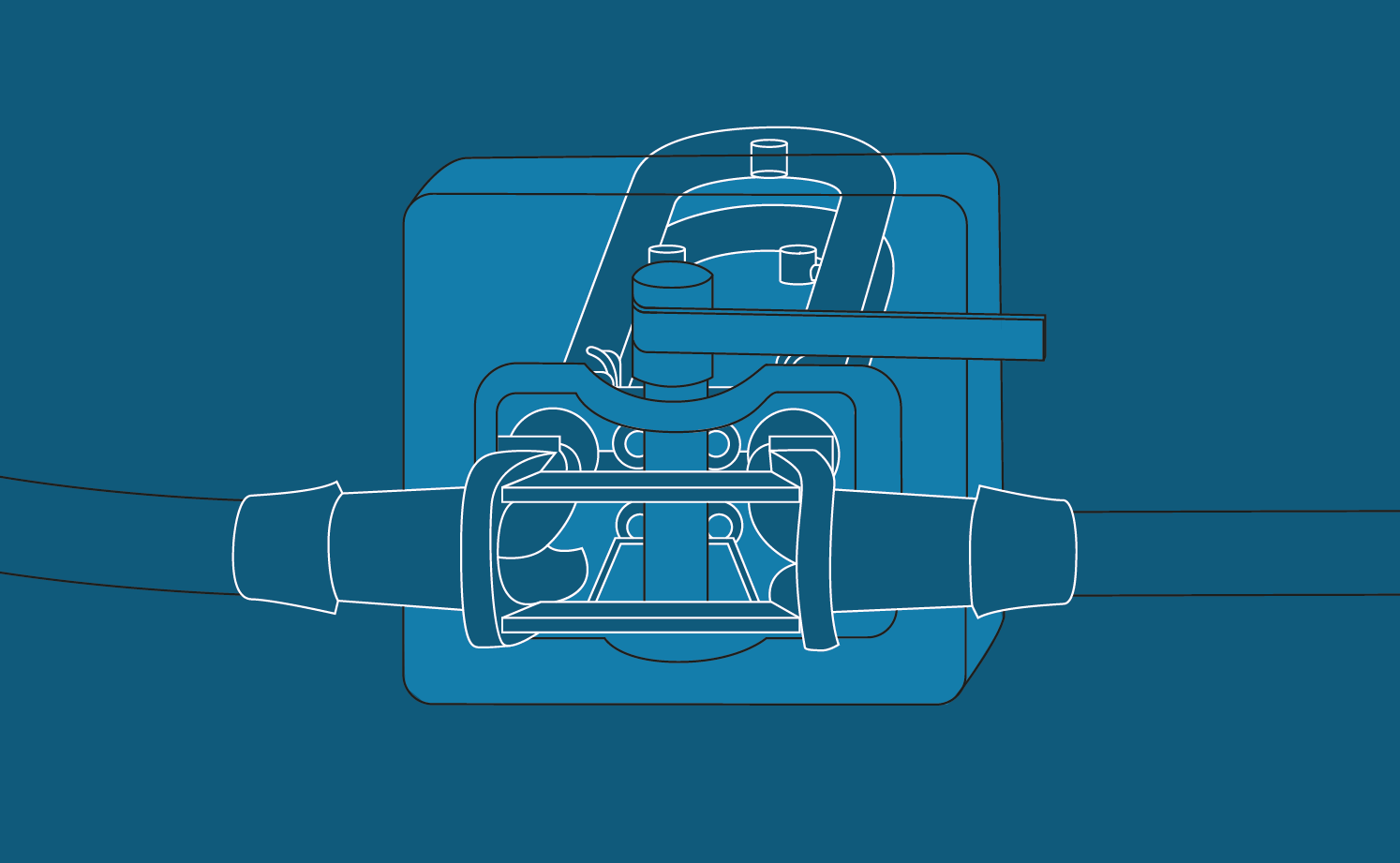

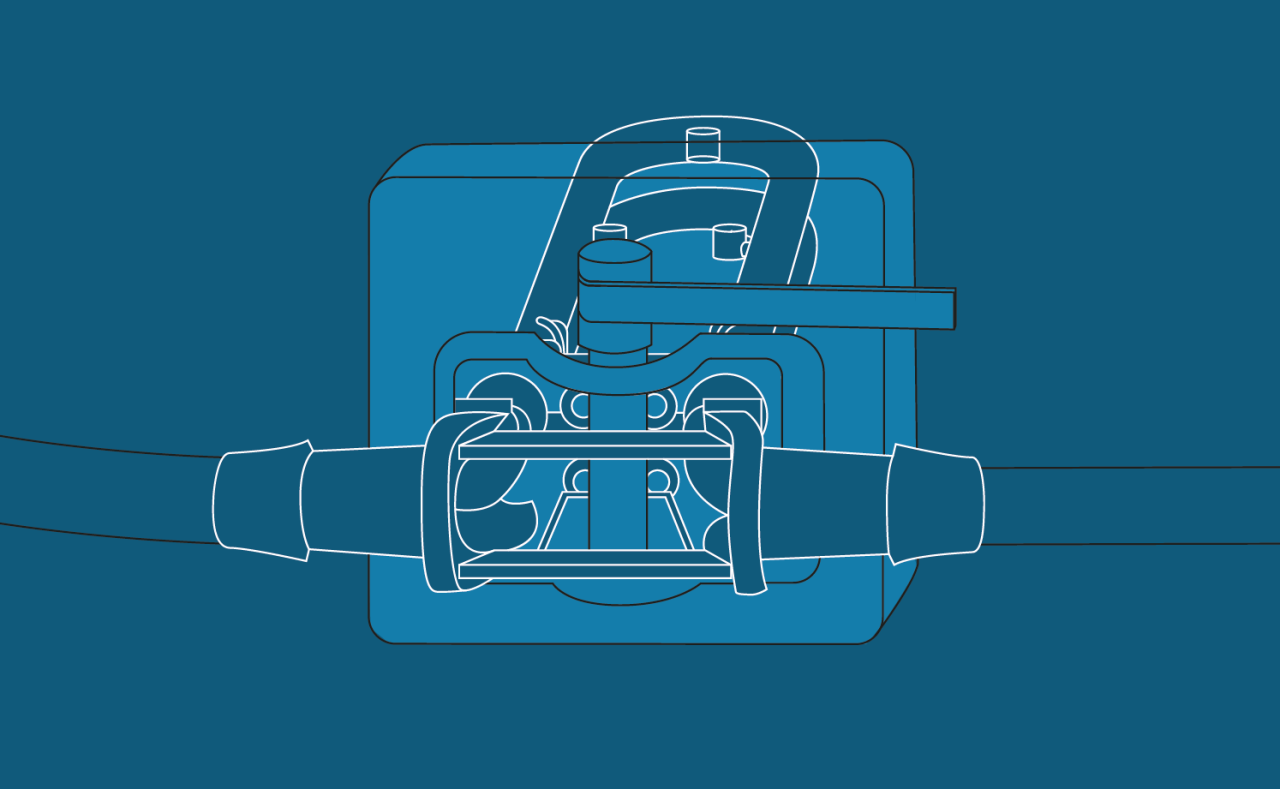

However, this growing segment has so far lacked a precision flow measuring instrument that also meets the strict cGMP standard. Coriolis technology would be ideal here, yet the complex arrangement inside a conventional instrument makes it far too expensive for single use. But that’s changing, with the Proline Promass U 500. The engineers’ trick is to make the instrument out of two separable parts. Power supply, exciter, sensors and signal processing all go in the base unit. But what the exciter sets in vibration, the measuring tube itself, becomes part of the disposable component. Just like in other high-quality, high-precision instruments, the tube is made of stainless steel; measurement accuracy is to within 0.5 percent. “This separation of the functional units makes Coriolis technology a viable economic proposition in the single-use sector,” says Samuel Neeser. And to ensure that the disposable component does not later end up in the trash, its constituent parts can be separated by material type and then appropriately recycled.

Published 20.05.2025, last updated 26.06.2025.

Dive into the world of the process industry through new exciting stories every month with our «changes» newsletter!