The taste of digitalization

Brewing beer with the help of an algorithm: a new multi-sensor system models the fermentation process in real time. The live feed from inside the tank is made possible by a combination of various measurement methods with IIoT technology.

IIOT

Fermentation is a key process in brewing, not to mention one of the most dynamic. In a fermentation tank, yeast produces alcohol from the sugars in the wort, along with carbon dioxide and a variety of aromas that together give the beer its fizz and flavor. Brewers must keep a close eye on the process to ensure that everything works as it should. They regularly monitor parameters such as residual extract, alcohol content and the degree of fermentation by taking samples, checking density using a hydrometer or laboratory analysis.

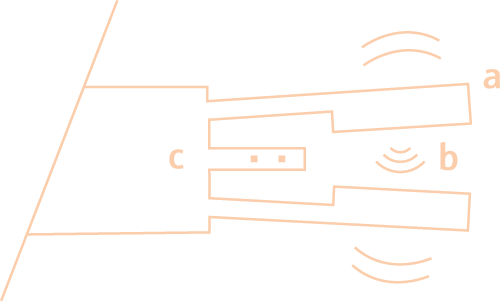

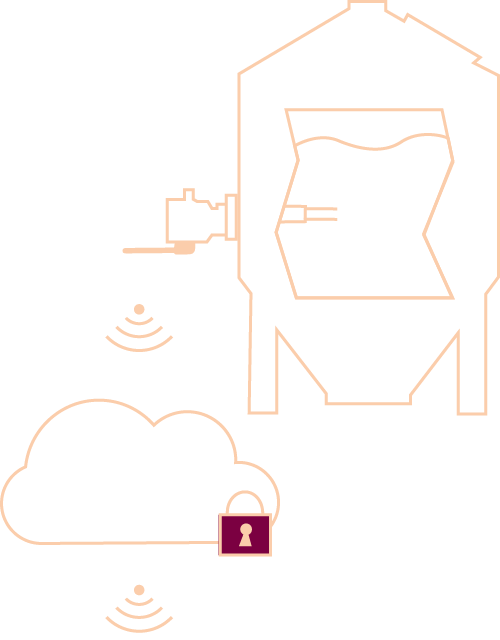

The new QWX43 fermentation monitor from Endress+Hauser makes all this effort a thing of the past. The system provides precision measurements of four parameters from directly inside the fermentation tank. The QWX43 uploads its data straight to Netilion, the Endress+Hauser cloud-based IIoT ecosystem, where an algorithm calculates all of the relevant fermentation parameters and enables real-time fermentation monitoring. “We developed a multi-sensor system and combined it with IIoT technology,” says product manager Julia Rosenheim. “Only then could we realize easy-to-use inline monitoring, accessible from anywhere.”

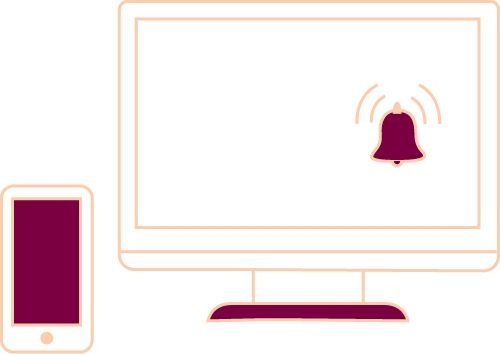

The fermentation monitor keeps the process under complete control without the brewers needing to be on site. And that’s not all: brewers can set alarms for each distinct stage of fermentation for different types of beer. They can even use a perfectly brewed batch as a reference. The system will then notify the brewers should the fermentation process deviate from the reference values. “Our system puts data in the brewers’ hands to optimize their fermentation process,” Rosenheim adds. “Now they can be certain that all their beer tastes just as good – exactly how their customers expect it to taste.”

Published 04.01.2023, last updated 16.01.2023.

Dive into the world of the process industry through new exciting stories every month with our «changes» newsletter!