Quality and care

Endress+Hauser flowmeters last for many years, sometimes decades. One plant in Munich has several that have passed their 30th anniversary — and are still going strong. What’s the secret to their longevity?

RELIABILITY

Egon Schneider sees many familiar objects when he walks through the hazardous waste management facility in Munich run by GSB Sonderabfallentsorgung Bayern. He has been with the company as an operations manager for 36 years – almost the same length of time as some of the plant’s meters that monitor processes and the resulting treated wastewater. “When the plant was built in the early 1990s, all the flow metering equipment was entrusted to Endress+Hauser,” says Schneider. “And a number of the Variomag and Pulsemag devices installed back then are still in service. They’re pretty much indestructible.”

That the instruments still work after such a long time is not a given, since hazardous waste disposal involves the chemical and physical treatment of organic and inorganic effluents such as oil-water mixtures, acids and alkaline solutions. “For this we use strong chemicals such as hydrogen peroxide, hydrochloric acid, sodium hypochlorite and limewater,” says Lara Peschke, team leader at the plant. Flow measurements regulate the dosage of these corrosive and abrasive liquids. Another challenge is that some of the chemicals inevitably leave deposits. “That’s why we need high-quality equipment that delivers precise measurements even under fluctuating process conditions,” she adds.

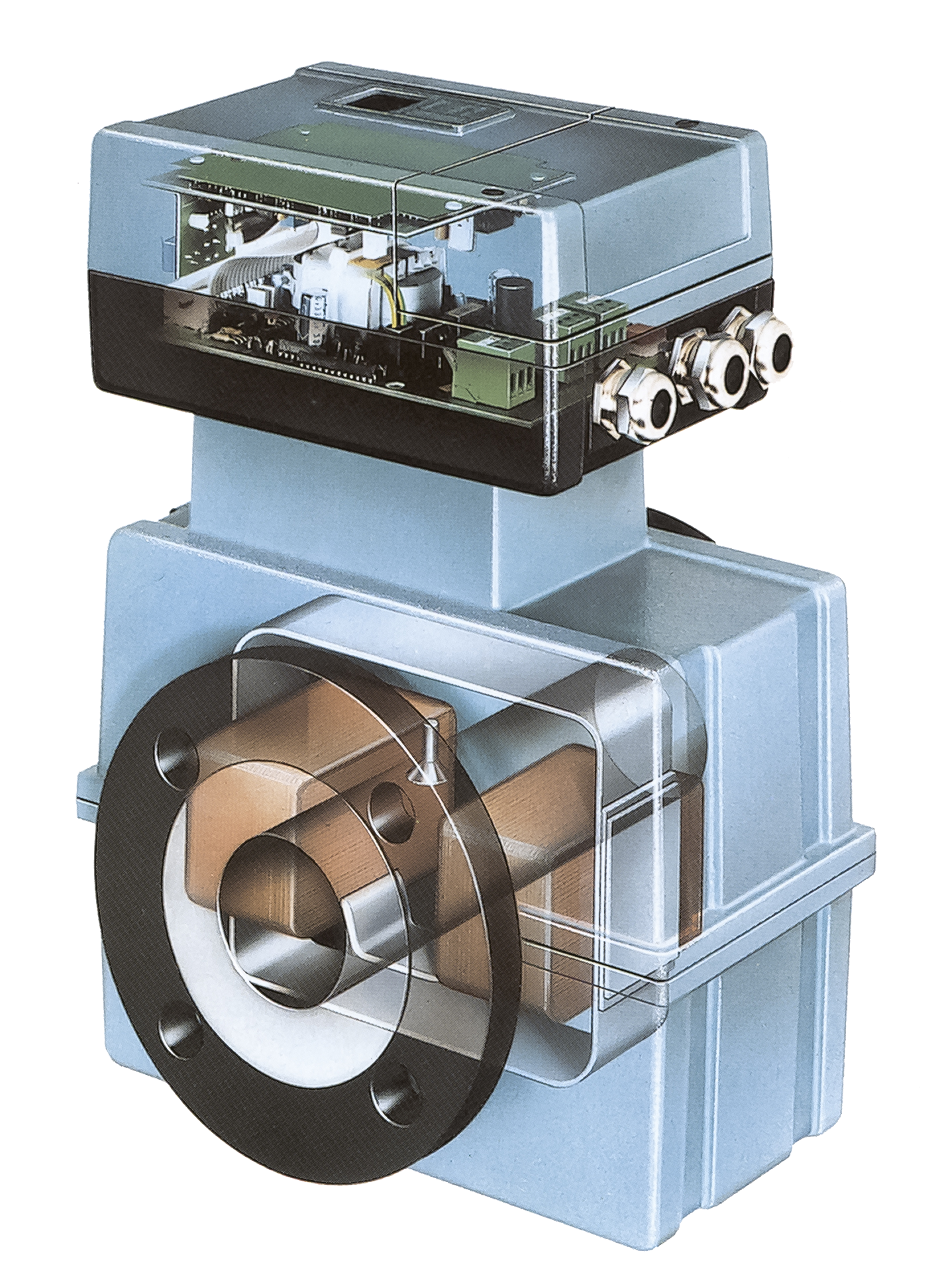

With this in mind, the engineers at the time favored electromagnetic flow metering, a robust technique that needs no moving parts and is totally reliable. In light of the facility’s strict requirements, many of the meters were coated with PTFE, a special plastic, and fitted with tantalum electrodes. GSB can also quickly spot when deposits are starting to form by analyzing chemical consumption or dosage figures. The in-house maintenance team then steps in and cleans the instruments. They also handle repairs – but calibration is left to Endress+Hauser. Internal and external expertise thus combine to keep the meters from showing signs of aging.

A small number of the measuring instruments have been replaced in recent years. “We chose Endress+Hauser again because we know from experience that their products are built to last,” says Peschke. The latest electromagnetic flowmeters are now in operation – with expectations for an equally long life.

Published 11.09.2023.

Dive into the world of the process industry through new exciting stories every month with our «changes» newsletter!