Sleep well with carbon dioxide technology

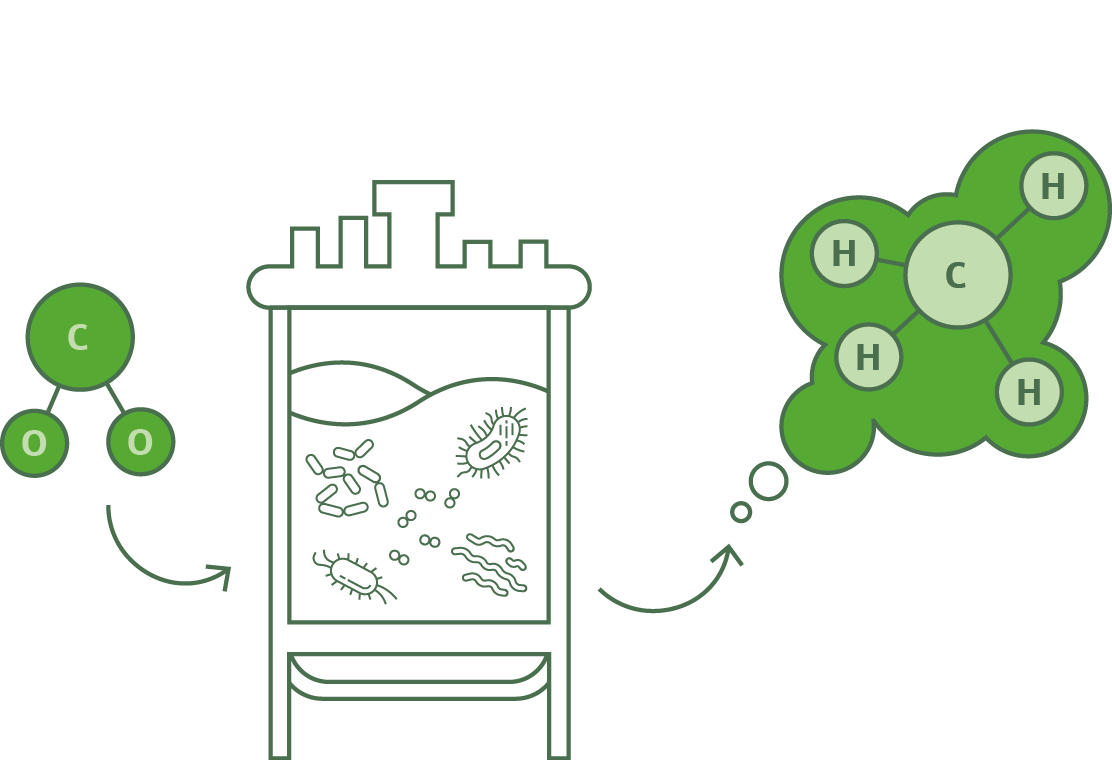

Covestro is one of the world’s largest polymer manufacturers. As a pioneer in the plastics industry, the company has fully committed itself to the circular economy; its endeavors include replacing raw materials such as crude oil with alternative sources. CO2 plays a central role in the strategy because it too contains that essential element, carbon. Covestro collaborated with partners to develop a groundbreaking process in which up to 20 percent CO2 is integrated into a chemical building block for plastics, thus conserving a corresponding amount of crude oil. To date the product has been used mainly to manufacture soft foam materials, such as for mattresses. What sounds simple is in fact complicated. “Carbon by itself does not readily bond with chemical compounds,” explains Jörn Matthies, Global Strategic Account Manager at Endress+Hauser. “But special catalyzers from Covestro and the Catalytic Center in Aachen are helping to make this difficult reaction possible at last.” Covestro manufactures its novel material in Dormagen. The requisite CO2 comes from exhaust outflows of nearby chemical plants. Instruments from Endress+Hauser monitor the process. Covestro relies on its instrumentation partner’s know-how at other locations as well. “We’re the primary global supplier of flow, level, temperature and analysis instrumentation,” explains Jörn Matthies.